Receiving a call in the middle of the night about an emergency at your facility is unnerving. Thoughts race through your head as to what the emergency could be. The most detailed written plans, employee training, fire protection systems, and fire prevention methods cannot eliminate the risk of industrial fires. However, they can significantly reduce your risk of monumental losses if a fire breaks out in your workplace. This is why preparing your business to respond to a fire and implementing fire prevention methods in day-to-day practices is prudent, responsible, and essential.

The Importance of an Emergency Response Plan

An Emergency Response Plan that details how to respond to emergencies, like fires, means that leaders can respond effectively to their departments. Swift responses to fires can minimize the amount of damage and losses to the building, and ultimately, the business. Be sure to include the different fire extinguishing systems installed in the Emergency Response Plan and familiarize the local fire department with all flammable and combustible materials present at the facility.

Further, assuring that employees are properly trained on evacuation protocol and knowing what to do when they first encounter a fire will pay off. Training employees to recognize alarm systems and to evacuate efficiently is not only required by OSHA’s 29 CFR 1910.38, but is a crucial part of a business’s continuity plan. A proper response that accounts for all individuals at a designated meet-up point allows the fire department to use all its resources to contain the blaze.

Take the time to coordinate with a select group of management personnel and establish an Emergency Response Team to lead different departments in an evacuation. Practice the response within the team—the more the team practices the response, the more ready the team will be once faced with the unexpected.

Fire Prevention

Still, the best step to take to prevent widespread fire from impacting a business is implementing preventative measures. Assess the facility to confirm fire extinguishers are properly spaced and readily accessible. Typically, an accessible fire extinguisher must be within 75 feet of where flammable liquids are used, processed, or stored in a facility. Work with a reputable fire extinguisher company to assess the combustible and flammable hazards that may be present.

Proper Housekeeping

Many fires in the workplace are due in part to poor housekeeping. While OSHA requires monthly inspections of fire extinguishers, frequent housekeeping inspections act as a preventative to spot risks before they pose a greater hazard. Frequently inspect electrical panels, electrical disconnects, and appliances to ensure that they are in good condition. Electrical fires can spread quickly. Electrical arcs, or discharges across a gap of air, can result in temperatures of several thousand degrees. Facilities where wood dust, fine plastic dust, or aluminum dust can accumulate are strongly recommended to establish a housekeeping program. Wiping down overhead surfaces, electrical panels, and transformers can prevent the accumulation of combustible dust from igniting.

Hot Work Procedures

Hot Work, which includes welding, torch cutting, brazing, soldering, and grinding, is one of the leading causes of industrial fires. Training your Maintenance Department on proper hot work procedures and permitting will empower them to take precautionary measures prior to undertaking one of these tasks. If hot work occurs frequently, designate an area for the work to occur that is free of combustible floors, walls, and materials. Make sure that contractors also follow hot work procedures, as the risk of fire can increase by 100% if contractors are not supervised.

Flammable/Combustible Liquid Storage

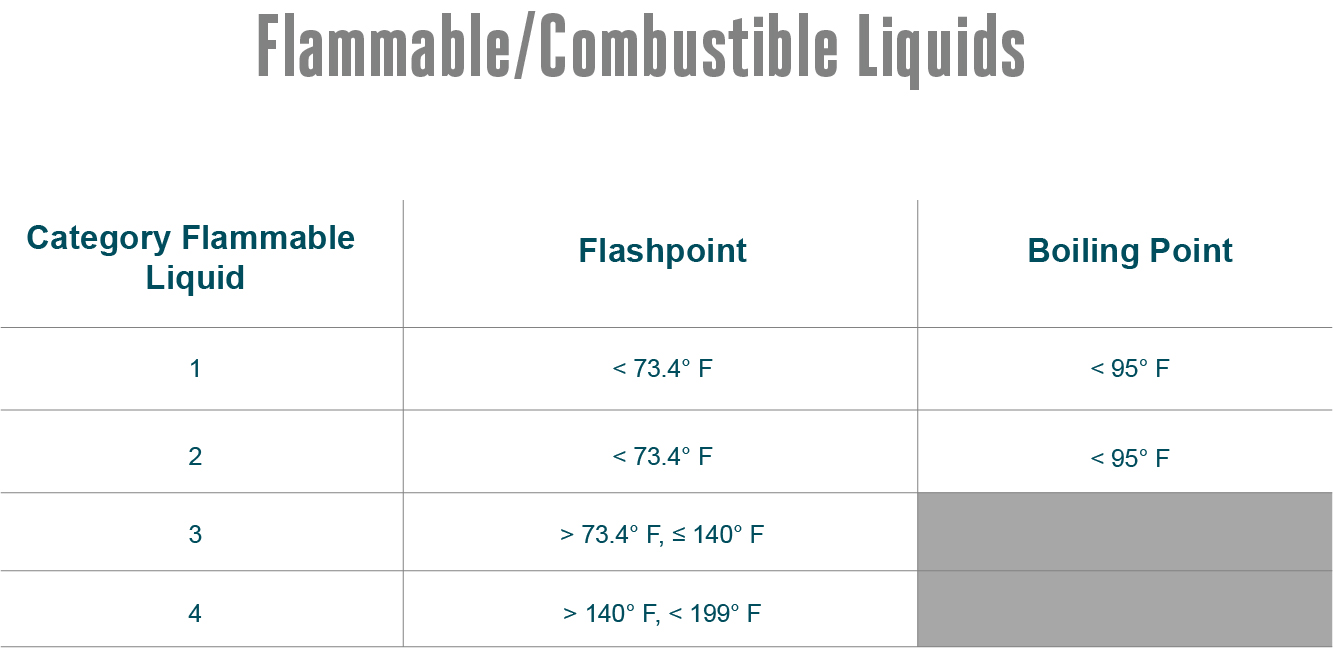

Improper storage of flammable liquids can also pose a significant risk to your business. OSHA’s flammable liquid standard 29 CFR 1910.106 limits the amount of flammable liquids that can be stored outside a flammable storage room or cabinet. OSHA divides flammable liquids into four categories: Categories 1, 2, 3, and 4. See the table below for more information.

Using the information in the table above, create an inventory of flammable liquids stored in general production areas of the facility. Only 25 gallons of Category 1 liquids may be stored outside of flammable storage cabinets and only 120 gallons of category 2, 3, 4 in containers such as drums. One exception to flammable storage is that 660 gallons of category 2, 3, or 4 is permitted in a single portable tank. A flammable storage room that meets the requirements in 29 CFR 1910.106(d)(4) may be needed to store all flammable materials safely and in a compliant fashion. For flammable liquids stored in a warehouse setting, be sure to refer to NFPA 30.

Spontaneous Ignition

What is frequently the culprit of “spontaneous ignition” is improper safeguards when it comes to dispensing flammable liquids and disposing of oily rags. Static discharge can naturally occur while pouring or pumping flammable liquids. If the container is effectively connected to the ground via a copper wire and a grounding rod, the static discharge is more likely to travel away from the flammable vapors while the flammable liquid is being poured. In addition to grounding the larger container, the smaller container being filled should also be “bonded” to the larger container via a conductive wire connection.

The other common way that spontaneous ignition occurs is by heat accumulating underneath oily rags. Oils and coolants often have flashpoints between 140° F and 199.4° F. Temperatures in this range can often be exceeded beneath 20 rags blanketed on top of one another. Procure FM-rated disposal cans to be emptied daily. Be sure to dispose of the rags in an environmentally responsible manner after collecting the rags from all areas.

Summary

Proper housekeeping implements safeguards that can reduce the risk of fire hazards to your business. Implementing these safeguards while developing and training upon a site-specific Emergency Response Plan keeps your facility prepared in case of fire and explosions. U.S. Compliance specializes in implementing comprehensive Emergency Response Plans and Hot Work Programs in a variety of industries. Contact U.S. Compliance today and see how we can best support your business to protect its assets.