OSHA’s Regulatory Agenda

Understanding OSHA’s regulatory agenda and priorities for 2021 can help your business maintain compliance and avoid costly fines. OSHA’s Regulatory Agenda and the recently published Site-Specific Targeted Inspections guidance help provide insight into regulatory areas that this year’s inspections will focus on. This information is critical for evaluating the likelihood of an OSHA inspection at your facility. More importantly, it can help you prioritize onsite health & safety initiatives for 2021 and beyond.

OSHA Inspection Strategy

OSHA has a priority hierarchy for conducting onsite inspections. The following details the criteria in order of precedence:

- Imminent Danger Situations – Hazards that could cause death or serious physical harm receive top priority.

- Severe Injuries & Illnesses – Workplace fatalities must be reported within 8 hours and hospitalizations/amputations/losses of eye must be reported within 24 hours. Failure to properly report these incidents to OSHA will likely result in an inspection.

- Worker Complaints – Allegations of hazards or violations receive a high priority by OSHA.

- Referrals – Hazards identified by other federal agencies, state/local agencies, individuals, and the media can result in inspections.

- Targeted Inspections – Inspections aimed at high-hazard industries or individual workplaces that have experienced high rates of injuries and illnesses.

- Follow-up Inspections – Checks for the abatement of violations cited during previous inspections are also conducted by OSHA in certain circumstances.

Site-Specific Targeted Inspections

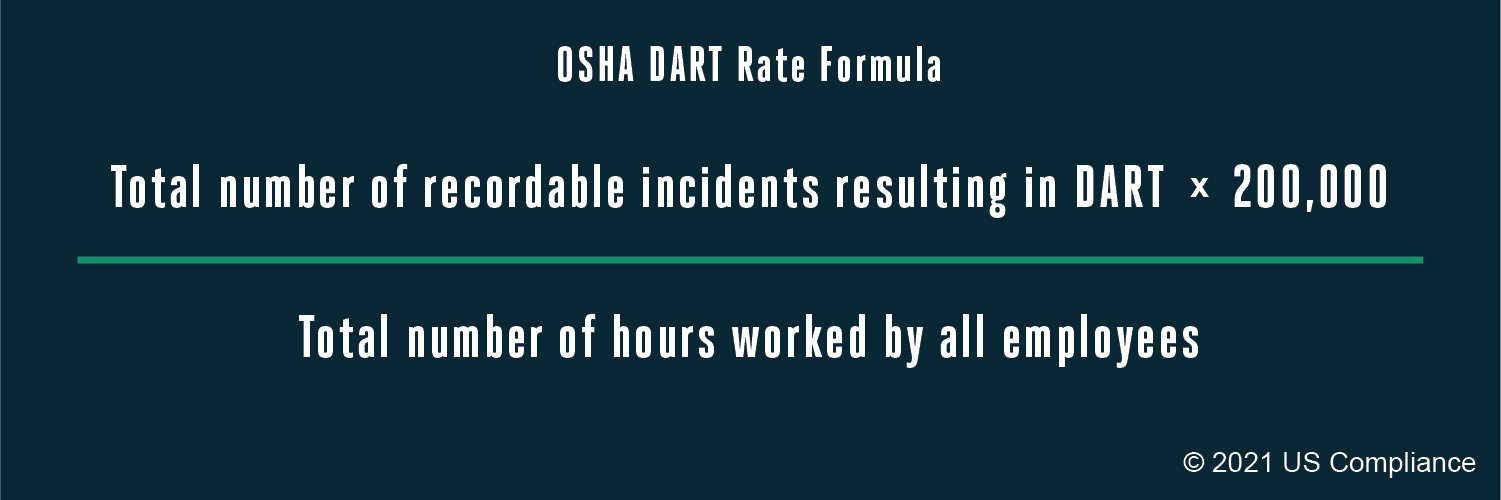

On December 14, 2020, OSHA established a directive that aims for Site-Specific Targeting (SST) of non-construction businesses with 20 or more employees. OSHA will review injury and illness data from 2017-2019 and target businesses who experienced consistent injury illness rate increases over the three-year data period. The agency will review DART rates (Days Away, Restricted, or Transferred) for facilities and compare those values against the industry’s national average. Facilities with DART rates consistently above the national average can be targeted by OSHA. OSHA will also target sites that failed to electronically submit their 300A OSHA Log between 2017-2019.

You can use the formula below to calculate the DART rate for your facility:

This table shows a listing of DART Rates by NAICS. You can use this data to see how your facility’s DART rate compares against the industry average. OSHA also has a helpful worksheet that you can use to record Incidence Rates.

National Emphasis Program

OSHA develops National Emphasis Programs (NEPs) in order to focus efforts on specific high-hazard industries. NEPs are evaluated by using available data from sources that include NIOSH reports, injury & illness data, and inspection data, among other available information. The following list provides examples of NEPs that OSHA has published. Businesses that process and manufacture these high-hazard materials and processes may be targeted for OSHA inspections.

- Combustible Dust

- Hazardous Machinery

- Hexavalent Chromium

- Lead

- Primary Metal Industries

- Process Safety Management (PSM)

- Respirable Crystalline Silica

You can find out more information on National Emphasis Programs specific to your industry here.

Local Emphasis Program

Similar to NEPs, Local Emphasis Programs (LEPs) are developed by OSHA to target high-hazard industries within a particular region. LEPs are created and implemented at the regional level and are aimed to help bring awareness and reduce/eliminate specific hazards in high-hazard industries within a region. Each region has a set of LEPs that OSHA has published. For example, in Region 5 (IL, IN, MI, MN, OH, WI), Local Emphasis Programs are the following:

- Fall Hazards in Construction and General Industry

- Grain Handling Facilities

- Powered Industrial Vehicles

- Wood Pallet Manufacturing Industry

You can find out more information on Local Emphasis Programs specific to your industry here.

What’s Ahead for OSHA?

With the new Administration, it is anticipated that there will be a greater focus on enforcing OSHA standards. Year-over-year, unprogrammed OSHA inspections have increased between 2017-2019. It can be expected that this trend will continue in 2021; this is especially likely considering the down year in 2020 due to the Covid-19 pandemic. As businesses move past Covid-19, OSHA will begin returning to a more normal inspection schedule.

Stay up to date with current OSHA guidance to help maintain regulatory compliance at your facility by visiting our website or contacting us.