Companies With a Pre-Existing Mandatory N95 FFR Respiratory Protection Program:

Because of the increased demand for N95 filtering facepiece respirators (FFRs) during the COVID-19 outbreak, and the resulting limitations on the availability of these respirators for use, OSHA has provided temporary compliance direction with 29 CFR 1910.134 (as it relates to mask selection and the associated requirements). First, if your company already has a mandatory respiratory protection program that requires N95 FFRs to be worn for protection against air contaminant exposure beyond OSHA Permissible Exposure Limits (PELs), then due to their limited supply, you should continue to try and secure those masks before moving on to alternatives.

In short, companies that have a pre-existing mandatory N95 FFR respiratory protection program should follow the revised OSHA enforcement guidelines when selecting alternative respirators (in order of priority):

- Companies may consider the use of alternative classes of respirators that provide equal or greater protection compared to an N95 FFR, such as NIOSH-approved, non-disposable, elastomeric respirators or powered, air-purifying respirators (PAPRs). Other filtering facepiece respirators, such as N99, N100, R95, R99, R100, P95, P99, and P100, are also permissible alternatives for those who are unable to obtain N95 FFRs.

- Implementing the hierarchy of controls in an effort to first eliminate workplace hazards, then use engineering controls, administrative controls, and safe work practices to prevent worker exposures to respiratory hazards.

- Prioritizing efforts to acquire and use equipment (in the following order):

- National Institute for Occupational Safety and Health (NIOSH)-certified equipment; then

- Equipment certified in accordance with standards of other countries or jurisdictions except the People’s Republic of China, unless equipment certified in accordance with standards of the People’s Republic of China is manufactured by a NIOSH certificate holder, in accordance with OSHA’s April 3, 2020, memo; then

- Equipment certified in accordance with standards of the People’s Republic of China, the manufacturer of which is not a NIOSH certificate holder, in accordance with OSHA’s April 3, 2020, memo; then

- Facemasks (e.g., medical masks, procedure masks).

- Prioritizing efforts to acquire and use equipment that has not exceeded its manufacturer’s recommended shelf life.

- Prioritizing efforts to use equipment that has not exceeded its intended service life (e.g., disposable FFRs used for the first time).

- Using homemade masks or improvised mouth and nose covers only, as a last resort (i.e., when no respirators or facemasks are available). Improvised masks are not personal protective equipment and, ideally, should be used with a face shield to cover the front and sides of the face.

Note: NIOSH-approved FFRs that employers require in the workplace should incorporate a full respiratory protection program, including medical evaluations for wearers, fit-testing, proper maintenance/care of respirators, and training. During the COVID-19 outbreak, OSHA field offices will exercise enforcement discretion concerning the annual fit-testing requirements due to potential shortages of fit-testing kits and test solutions (e.g., Bitrex, isoamyl acetate), as long as companies have made good-faith efforts to comply with the requirements of the Respiratory Protection standard and to follow the guidelines outlined in this document.

Safety Guidelines for Extended Use or Reuse of FFRs (N95s)

OSHA has advised that N95 FFRs that are beyond their manufacturer’s recommended shelf life will provide greater protection than surgical masks (i.e., facemasks other than surgical N95s; see below) or non-NIOSH-approved masks (e.g., homemade masks or improvised mouth and nose covers, such as bandanas).

The Centers for Disease Control and Prevention (CDC) and National Institute of Occupational Safety and Health (NIOSH) believe the following products, despite being past their manufacturer-designated shelf life, should provide the expected level of protection to the user if the stockpile conditions have generally been in accordance with the manufacturer-recommended storage conditions and an OSHA-compliant respiratory protection program is used by employers. In alphabetical order, these models include the following:

- 3M 1855

- 3M 1860

- 3M 1870

- 3M 8210

- 3M 9010

- 3M 8000

- Gerson 1730

- Medline/Alpha Protech NON27501

- Moldex 1512

- Moldex 2201

In the event that the extended use or reuse of N95 FFRs becomes necessary, the same worker is permitted to extend the use of or reuse the respirator, as long as the respirator maintains its structural and functional integrity and the filter material is not physically damaged, soiled, or contaminated (e.g., with potentially infectious material, oil, paint). Companies need to address the circumstances under which a disposable respirator will be considered contaminated and not available for extended use or reuse in their written Respiratory Protection Programs. Extended use is preferred over reuse due to the contact transmission risk associated with donning/doffing during reuse. When respirators are being reused, employees must understand the following:

- The respirator must only be used and reused by a single wearer.

- Be aware of your personal health considerations prior to wearing a respirator.

- Users should perform a user seal check each time they don a respirator and should not use a respirator on which they cannot perform a successful user seal check.

- Employees must understand that if the structural and functional integrity of any part of the respirator is compromised, it should be discarded. Over time, components such as the straps, nose bridge, and nose foam material may degrade, which can affect the quality of the fit and seal.

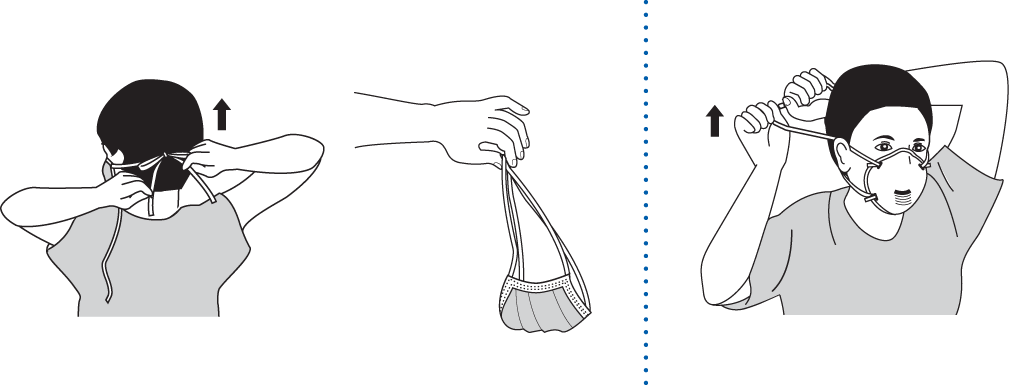

- If reuse of respirators is necessary, an appropriate sequence for donning/doffing procedures should be used to prevent contamination.

- Consider the front of a mask/respirator as contaminated – avoid touching it.

- If your hands get contaminated during mask/respirator removal, immediately wash your hands or use an alcohol-based hand sanitizer.

- Grasp bottom ties or elastics of the mask respirator, then the ones at the top, and remove without touching the front.

- Discard in a waste container.

- Immediately wash your hands after removing the mask/respirator.

Source: CDC’s PPE Sequence

Safety Guidelines for Use of Expired FFRs (N95s)

N95 FFRs may be used beyond the manufacturer’s recommended shelf life if new N95s are not available. When expired respirators are being reused, employees must understand the following:

- The respirator must only be used by a single wearer.

- Be aware of your personal health considerations prior to wearing a respirator.

- Use only previously NIOSH-certified expired N95 FFRs and be sure that employees understand that they are using expired N95s.

- Purchasers and users of respirators should not co-mingle products that are past their manufacturer’s recommended shelf life with items that are within their shelf life.

- Employees must understand that if the structural and functional integrity of any part of the respirator is compromised, it should be discarded.

Companies Without a Pre-Existing Mandatory N95 FFR Respiratory Protection Program:

Companies without a mandatory use respiratory protection program have some options. These are typically companies that have current industrial hygiene testing data available that demonstrates that workplace air contaminant exposure levels do not exceed OSHA Permissible Exposure Limits (PELs) and/or may have historically provided N95 FFRs for use on a strictly voluntary basis. During the current COVID-19 outbreak, certain states may also require that workplace employees wear a mask or face covering when they either cannot or, it is impractical to maintain 6 feet of physical distance between themselves and others.

- NIOSH-approved N95 FFRs would be the best option for voluntary use, if they are available, as these are considered respirators that reduce the wearer’s exposure to airborne particles, from small particle aerosols to large droplets. N95 respirators are tight-fitting respirators that filter out at least 95% of particles in the air, including large and small particles.

Note: NIOSH-approved N95 FFRs do not require a full respiratory protection program if they are strictly for voluntary use. In this case, the primary requirement for companies is to provide a copy of Appendix D to 29 CFR 1910.134 for the wearers. Keep in mind that mandatory use of N95 FFRs would require several additional elements such as a written program, medical evaluation, training, and fit testing.

- Surgical facemasks are another option if N95 FFRs are not available. However, unlike NIOSH-approved N95s, facemasks are technically not considered respirators. Facemasks are loose-fitting and provide only barrier protection against droplets, including large respiratory particles. Fit testing and user seal checks are not necessary with facemasks. Most facemasks do not effectively filter small particles from the air and do not prevent leakage around the edge of the mask when the user inhales. Nonetheless, they are an option during the COVID-19 outbreak due to the current shortage of N95 respirators.

- Where surgical facemasks are not available, companies may permit the use of cloth masks (these are available through select companies) or homemade masks (e.g., bandana, scarf) as a last resort. However, homemade masks are not considered PPE, since their capability for protection is unknown. Caution should be exercised when considering this option.

General Safe Guidelines for Use/Reuse of Facemasks, Cloth or Homemade Masks

- Must only be used and reused by a single wearer.

- Be aware of your personal health considerations prior to wearing a mask.

- Visually inspect the mask before use to ensure it remains in good shape. Masks should be removed and discarded if soiled, damaged, or if they are hard to breathe through.

- Not all facemasks can be reused:

- Facemasks that fasten to the provider via ties may not be able to be undone without tearing and should be considered only for extended use, rather than reuse.

- Facemasks with elastic ear hooks may be more suitable for reuse.

- Facemasks should be carefully folded so that the outer surface is held inward and against itself to reduce contact with the outer surface during storage. The folded mask can be stored between uses in a clean, sealable paper bag or breathable container. Masks should not be stored in pockets, plastic bags, or other confined areas.

- To avoid contamination, avoid touching the insides of masks as well as the exterior of the masks upon removal

- Individuals should be careful not to touch their eyes, nose, and mouth when removing their face covering and wash hands immediately after removing.

- Cloth masks or face coverings should be able to be laundered and machine dried without damage or change to their shape.

- Perform hand hygiene with soap and water or an alcohol-based hand sanitizer before and after touching a used mask.

- Masks should be packed or stored so that the respirators do not become damaged or deformed.

- Discard a mask if contaminated with blood, respiratory or nasal secretions, or other bodily fluids.

- If homemade masks must be used as a last resort in a health care setting, they should ideally be used in combination with a face shield that covers the entire front (extending to the chin or below) and sides of the face.

- It is critical to emphasize that maintaining 6 feet of social distance and vigilant handwashing remains important to slow the spread of the virus.

Training Requirements for N95 FFRs, Facemasks, Cloth or Homemade Masks

Employees must receive some level of training concerning the type of respirator or mask they will be wearing.

- Companies must provide a copy of Appendix D to 29 CFR 1910.134 for wearers of NIOSH-approved N95 FFRs that are voluntarily worn.

- NIOSH-approved N95 FFRs or other types of respirators that companies require their employees to wear require a full respiratory protection program – including the training component:

- Why the respirator is necessary

- Purpose of the medical evaluation

- How to recognize health-related signs and symptoms during use

- Limitations and capabilities of the respirators

- How to use respirators effectively

- How to inspect the respirator and protocol for replacement

- The process for completing an assessment of comfort

- How to put on and remove

- How improper fit, usage, or maintenance can compromise the protective effect of the respirator

- How to perform a user seal check each time the respirator is put on

- Maintenance and storage procedures

- Fit testing requirements

In addition, the following training topics should be included for any employees that are provided with FFRs, face coverings or cloth/homemade masks:

- The types of masks available and the reason(s) they are provided or required

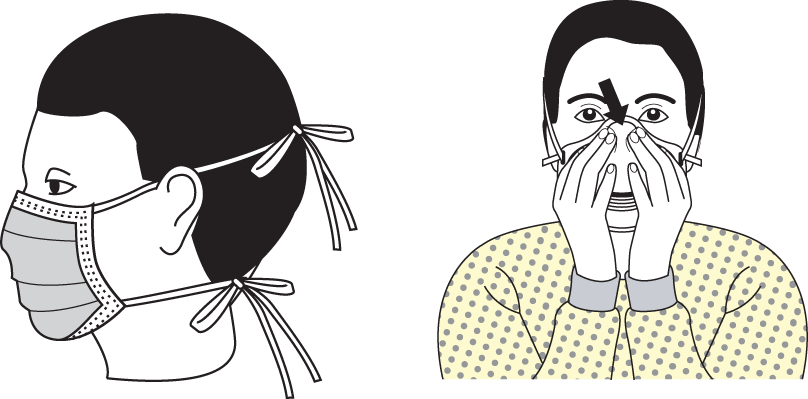

- How to properly put on a mask or respirator and perform a seal check (if tight-fitting respirator):

Source: CDC’s PPE Sequence

- Secure ties or elastic bands at the middle of head and neck

- Fit flexible band to the nose bridge

- Fit snug to face and below the chin

- Fit check respirator (inhale – respirator should collapse around the face; exhale – check for leakage around the face)

- Storage parameters and the importance of not co-mingling masks and respirators

- Safe guidelines for extended use or reuse of N95s

- Safe guidelines for use of expired N95 FFRs

- General safe guidelines for use/reuse of facemasks, cloth, or homemade masks

- Using homemade masks or improvised mouth and nose covers are used strictly as a last resort (i.e., when no respirators or facemasks are available). Improvised masks are not personal protective equipment and, ideally, should be used with a face shield to cover the front and sides of the face.